The guiding principles of the manufactory. Quality Made in Germany.

When the first bike from vsf fahrradmanufaktur rolled onto Germany's roads in 1987, the bicycle was a serious means of everyday transportation for only a few people. But even back then, the founders of vsf fahrradmanufaktur had the vision of making a contribution to our environment with exclusively handmade bicycles. With great attention to detail and a soft spot for steel frames, they set up a manufactory and focused on handmade premium bicycles - durable, robust and of particularly high quality.

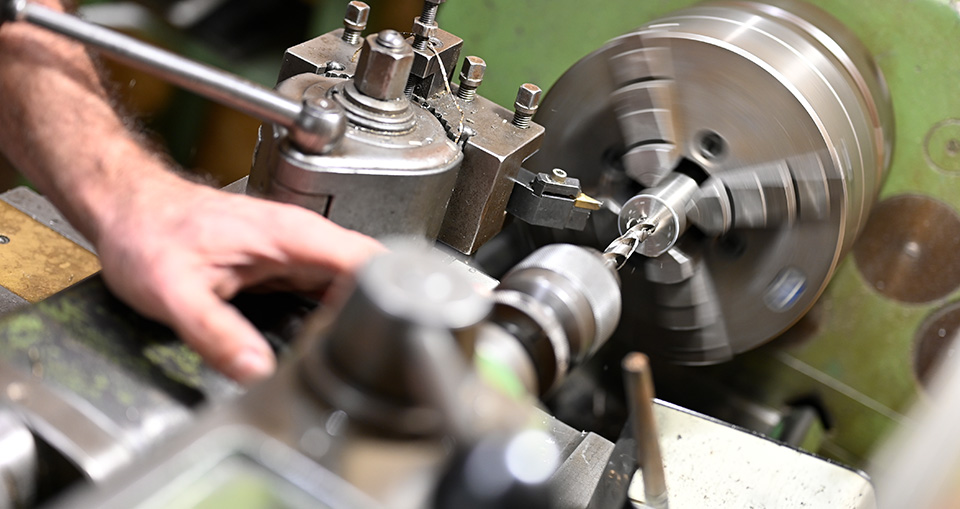

Classic craftsmanship, modern technology.

We feel a particular obligation to fulfil the manufacturing ideals of our early days. To this day, all vsf fahrradmanufaktur bicycles are put together, built and carefully tested here at our Oldenburg manufactory in Lower Saxony. Special paint jobs are applied with great attention to detail as powder coatings on our own painting line in Oldenburg.

Today, as before, frames for particularly special models are manufactured by hand at a small south-German blacksmithing workshop focusing on the finest traditional craftsmanship.

The majority of our frames today come from carefully selected production partners outside Germany. We almost exclusively use steel frames which – regardless of whether they are produced within or without Germany – are always the result of demanding workmanship.

When looking for these partners, we place the utmost importance on companies that identify with our manufacturing philosophy, sophisticated quality management and our quest for particularly high-quality and sustainable bicycles.

Focus on product quality

Outstanding product quality is the traditional key focus of vsf fahrradmanufaktur – from the idea through the design to the final assembly. Thanks to our 3D printers, we are already able to develop custom-fit components and frame elements at the development phase, simulating their interactions perfectly.

In this way, we develop high-quality bicycles based on steel frames for the particular needs of our customers – providing an incomparable riding experience. In doing so, we always use high-quality, sustainable materials combined with harmoniously adjusted brand-name components. Environmentally friendly production processes, e.g. in our in-house painting line for solvent-free powder coatings, complete our profile as a sustainable bicycle manufacturer.